Enhancing Portable Electric Water Bottles with Waterproof Breathable Membrane Technology

In modern fast-paced life, portable electric water cups have become a must-have for many travelers and office workers because of their convenience and practicality. However, have you ever thought that a small breathable membrane has added new highlights to this product? This article will explore the importance of waterproof breathable membranes in portable electric water cups to help you better understand this magical product.

In order to seize this opportunity, a well-known leading manufacturer of lightweight water cups hopes to optimize the performance of portable electric water cups and simplify the manufacturing process. However, its appearance design is particularly small. To achieve the above goals, they found Shi Bode.

Ⅰ.Project Pain Points

Traditional electric water cups need to open the cup lid to release steam when heating, otherwise the cup will be deformed or damaged due to pressure differences, but this action will have the following effects on the user experience:

![]() Safety risks: Opening the lid to boil water not only increases the risk of burns but also may cause steam burns to the user.

Safety risks: Opening the lid to boil water not only increases the risk of burns but also may cause steam burns to the user.

![]() Tedious use: The need for users to frequently open and close the lid during boiling water undoubtedly increases user inconvenience.

Tedious use: The need for users to frequently open and close the lid during boiling water undoubtedly increases user inconvenience.

![]() Hygiene and safety: When the lid is open for boiling water, external dust, bacteria, and other pollutants can easily enter the cup, affecting the hygiene of the water. This is a non-negligible issue for health-conscious users.

Hygiene and safety: When the lid is open for boiling water, external dust, bacteria, and other pollutants can easily enter the cup, affecting the hygiene of the water. This is a non-negligible issue for health-conscious users.

![]() Noise issues: The open lid during boiling produces a loud noise, affecting the user experience. Especially in quiet places, this noise may cause discomfort to others.

Noise issues: The open lid during boiling produces a loud noise, affecting the user experience. Especially in quiet places, this noise may cause discomfort to others.

![]() Heat loss: When the lid is open, heat is quickly lost, leading to extended heating times. This not only wastes electricity but also prolongs waiting times, affecting the user experience.

Heat loss: When the lid is open, heat is quickly lost, leading to extended heating times. This not only wastes electricity but also prolongs waiting times, affecting the user experience.

![]() Water evaporation: With the lid open during boiling, water evaporates, reducing the water capacity. This not only affects the taste of the water but may also cause the water to boil dry, increasing safety risks.

Water evaporation: With the lid open during boiling, water evaporates, reducing the water capacity. This not only affects the taste of the water but may also cause the water to boil dry, increasing safety risks.

Ⅱ. Solution

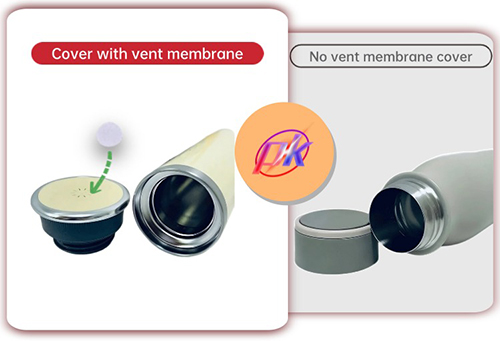

In order to solve the above pain points, Shi Bode, relying on industry experience and its own outstanding capabilities, proposed a solution for it, that is, to open a few holes in the cup lid and then weld a breathable membrane. This solution not only improves the safety and practicality of the product, but also enhances the user experience. Subsequently, Shi Bode tested the product again.

Finally, SST combined its expertise in acoustic performance, gas diffusion and waterproof applications to create a unique performance solution for portable electric water bottles.

Ⅲ.Performance test

ⅰ Noise test

The working noise of electrical appliances is inevitable, but from the perspective of customer experience, they will also choose appliances with less noise. The test environment is in the same room, and the indoor noise floor is 40 decibels. I used a noise meter to test the sound throughout the process, and then intercepted the maximum noise value during the boiling process of the portable water bottle. Let’s take a look at the test results:

The working noise is around 50 decibels, which is within the acceptable range of the human ear, and there is no sharp and piercing noise.

ⅱBoiling time test

The rated power of these models is 300w-350w. Let’s see the actual power, that is, how long the water is boiled. Test conditions: water at room temperature, about 300ml, heated to 100℃.

It can be seen that the boiling time of these two electric water bottles is similar.

ⅲ Sealing test

The sealing of the electric water bottle without breathable membrane was not tested, and only the electric water bottle with breathable membrane was tested.

After filling the electric water bottle with breathable membrane with water, and then covering the lid, repeatedly shaking and shaking the cup, the test results showed no leakage.

Ⅳ.Conclusion

With the development of technology, theVent Membrane technology is becoming more and more mature, which provides more reliable protection for our portable electric water bottle. Choosing an electric water bottle equipped with aVent Membrane is not only a convenience, but also a safety and security. Let us enjoy the convenience brought by technology together, while ensuring that our equipment can operate stably in various environments.

Product information: Welded vent membrane

Breathable membrane material: ePTFE

Air permeability: ≥600ml/min@7kPa (customizable)

Water pressure resistance: ≥70kPa, 50s (customizable)

Protection level: IP67/ IP68/ IP69K (customizable)

Working temperature: -40℃–160℃

Surface properties: hydrophobic/oleophobic (customizable)