e-PTFE Waterproof Vent Valve Selection Guide

🌧️ Introduction: Waterproof breathable valves are an indispensable component in modern industry and consumer products. They not only protect equipment from moisture damage but also ensure breathability, thus extending the product’s lifespan. Among the many waterproof breathable valves, e-PTFE (expanded polytetrafluoroethylene) waterproof breathable valves are highly favored for their superior performance. Today, we will delve into the selection principles of e-PTFE waterproof breathable valves.

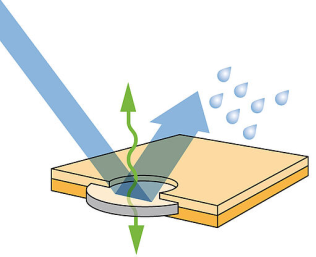

🔍 Understanding e-PTFE: e-PTFE is an advanced material known for its unique microporous structure. These micropores are small enough to block moisture and other liquids, yet large enough to allow gases to pass through freely. This characteristic makes e-PTFE an ideal choice for manufacturing waterproof breathable valves.

🏭 Schipper’s Professional Perspective: As a leading provider of waterproof breathable solutions, Schipper understands the importance of correct selection. Their products are widely used in various fields such as automotive electronics, electronic equipment, outdoor gear, and more.

📐 Selection Principles:

Environmental Adaptability: Consider the environmental conditions the equipment will face, such as temperature, humidity, chemical exposure, etc. e-PTFE material performs well under these extreme conditions, but its specific performance still needs to be assessed according to product specifications.

Breathability Requirements: Choose the appropriate breathability based on the heat and moisture generated by the equipment. Too high breathability may lead to moisture ingress, while too low may affect the equipment’s heat dissipation efficiency.

Size and Installation: Ensure that the size of the breathable valve is compatible with the equipment’s interface, and consider the convenience and safety of installation, with options for threaded and snap-fit installations.

Flow Requirements: For applications requiring rapid gas exchange, choose a breathable valve with higher flow capacity.

Durability: Consider durability under long-term exposure to harsh environments, and select a breathable valve that can resist UV rays, chemicals, and other corrosive factors.

🔍 Case Study: Schipper once provided a customized waterproof breathable valve for an outdoor electronic equipment manufacturer. The device needed to operate under extreme weather conditions, hence the high requirements for the breathable valve. Schipper offered a breathable valve with high breathability and excellent waterproof performance based on the customer’s specific needs, ensuring the stable operation of the equipment.

📚 Theoretical Explanation: The working principle of the waterproof breathable valve is based on its microporous structure. When water vapor molecules attempt to pass through these micropores, they condense into droplets due to surface tension and are thus blocked. Meanwhile, gas molecules can pass through freely, maintaining the equipment’s breathability.

🔍 User Characteristics: Users of waterproof breathable valves typically prioritize product durability and performance. They may come from industries such as electronics, outdoor electronic devices, automotive electronics, etc., and have high requirements for product quality and reliability.

🤔 Psychology and Human Nature: When choosing a waterproof breathable valve, users often consider the long-term benefits and cost-effectiveness of the product. The right choice can not only protect the equipment but also enhance the user experience, thereby increasing brand trust.

🎯 Conclusion: Correctly selecting a waterproof breathable valve is crucial for ensuring equipment performance and longevity. Schipper’s professional solutions, combining advanced materials and high-performance design, can meet the needs of various demanding environments.